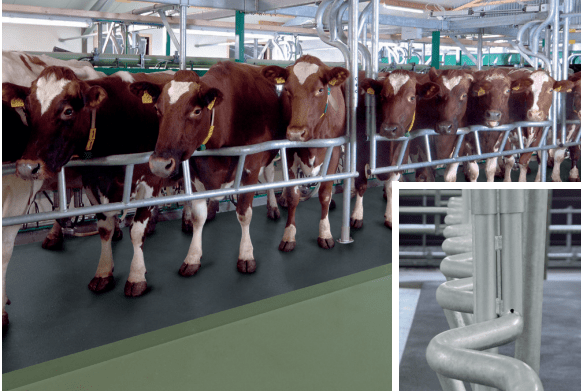

Great space-saving design

With its time and space saving design, the EuroClass 800/850 herringbone milking parlour is simply unbeatable when it comes to efficiency. The short distances between cow positions (800/850 mm modular dimension) allow sufficent space for the animals to be monitored individually and for the cluster to be applied comfortably through the back legs. Result: More milking places in the same amount of space as a conventional parlour – giving lower construction costs!

Simply unbeatable efficiency High efficiency

level’s in a successful parlour are achieved where everything runs smoothly and without any stress. The animals enter and leave the milking parlour calmly and quickly through wide passageways. The freestanding, animal-friendly frame design ensures excellent cow position and optimum operator working space, with shorter walking distances and a clear view of the udder. Result: faster access and shorter milking times.

With a clear overall view

Regardless of what equipment is installed at the milking place for the operator, milking in the EuroClass 800/850 means: Less stress, higher productivity and enough time and space to ensure careful milking and monitoring of the animals.

The throughput accelerator

Two words for a great step forward: “Rapid Exit“ is the name of the EuroClass range that has been designed for medium-sized herds. The crucial difference from the conventional herringbone milking parlour is the new front exit. The effect: “turbo-speed” exit, much higher throughput, more time saved and greater efficiency

The figures prove it

With the rapid exit, the time spent moving the animals is approx. 50% shorter compared to a conventional EuroClass 800/850 of the same size. With shorter waiting times for the animals, this means that the through-put is increased by up to 15%. So the rapid exit of your animals is your way into a higher level of productivity.

Positioning bonus

The breast rail is curved to match the shape of the animals, enabling fast, perfect positioning of the animals. The effect: time saved thanks to faster application of the clusters, less stress for the operator and animals. Result: improved letdown because there is less stress on the animals. Another bonus is the flexible height adjustment of the breast rail which can be adjusted to suit the different breed sizes.

The gateway to success

Gate controls at milking place with Metatron P/S 21 speed up the group changeover and make work easier for the operator. The integrated DPNet gate controls are clearly designed and easy to use and can be operated from any milking place. This cuts down the distances that operators have to cover and noticeably saves time on the group changeover.